Laser technology for new energy applications

Are you active in the field of hydrogen and battery technologies?

New energy and mobility concepts require new approaches in terms of development and construction. The shift in the automotive market from exhaust components to electromobility components are supported with our solutions. This has also opened the generation, storage and usage of hydrogen as an environmentally neutral fuel.

Benefit from our knowledge and experience on products with processing technologies in the field of laser cutting and laser welding. In order to bring a required workpiece onto the market, a variety of steps are needed. We support you in all phases of the ramping up so you can take a decision on the best way of manufacture and with a clear conscience invest in your future production capability:

from feasibility over prototypes to series production.

Our solutions for your hydrogen and battery applications

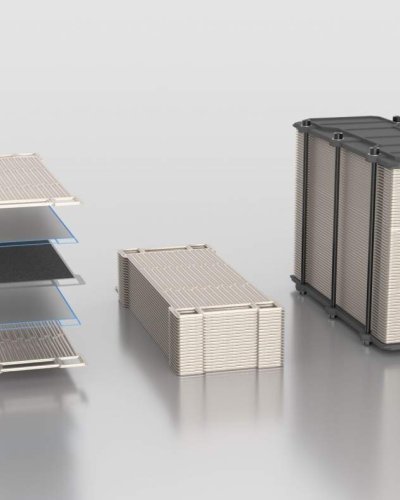

Turnkey lines for laser welding of metallic bipolar plates

Our patented welding module for the production of bipolar plates for fuel cells and electrolyzers reliably achieves very high absolute welding speeds of 1 m/sec with a large usable working area, which enables annual production of several million units. The static structure between optics and clamping technology guarantees the highest accuracy and reproducibility.

For the validation we can also offer contour cutting and leakage testing via our technology partner Zeltwanger.

Turnkey lines for laser welding of battery housings

With a cartesian welding system, our Laser Welding Cell for battery cases and housings can not only weld the case, but also do pre- and assembly of components, as well as DMC markings. The material can be stainless steel or aluminium alike.

The footprint is minimal and offers interchangeable tooling to offer high flexibility. The system is designed for manual loading as well as fully automated and integrated in assembly lines.

Turnkey lines for laser welding of battery cell contacts

Our Laser Welding Cell for cell contacts - prismatic, round or pouch cells, enables process-parallel loading and unloading as well as high flexibility for geometric contour changes thanks to its innovative scanner optics with vision system. Further process steps such as assembly of add-on components, DMC labeling or other welding processes (terminal bus, etc.) can be integrated into the system.

Turnkey lines for laser welding of battery cooler plates

Thermal management is an important component of a traction battery system that must meet the highest requirements. Our Laser Welding Cell is equipped for welding stainless steel as well as aluminum with very good welding results and uniform welding depths at welding speeds of up to 15 m/min.

For the validation we can also offer contour cutting and leakage testing via our technology partner Zeltwanger.

Our services

In our TechCenter, we offer validation and prototype production for series production, which means that we weld and cut using the same technology as our series modules: where possible, the tools manufactured and used for this are always the same.

We do:

> feasibility & validation

> prototypes & preseries

> system design & planing

> plant production & commissioning

Would you like a personal consultation with our experts or information about our products and services?

We will be happy to advise you individually and free of charge on your manufacturing potential. Please contact us!