Because your future matters

Become a part of Weil Technology

We are Weil Technology, a family-owned machine engineering company based in Müllheim/Germany. With our company you can find your success because we work on a daily basis with fun and interesting projects and keep your perpespective for the future in mind.

Great things are never created alone. Together with our technical-inclined and creative, enthusiastic employees we realize fascinating solutions.

Are you in?

We look forward to improving our company with your talent. There are many different ways to join us. Take your next step and apply today!

We are Weil Technology

-

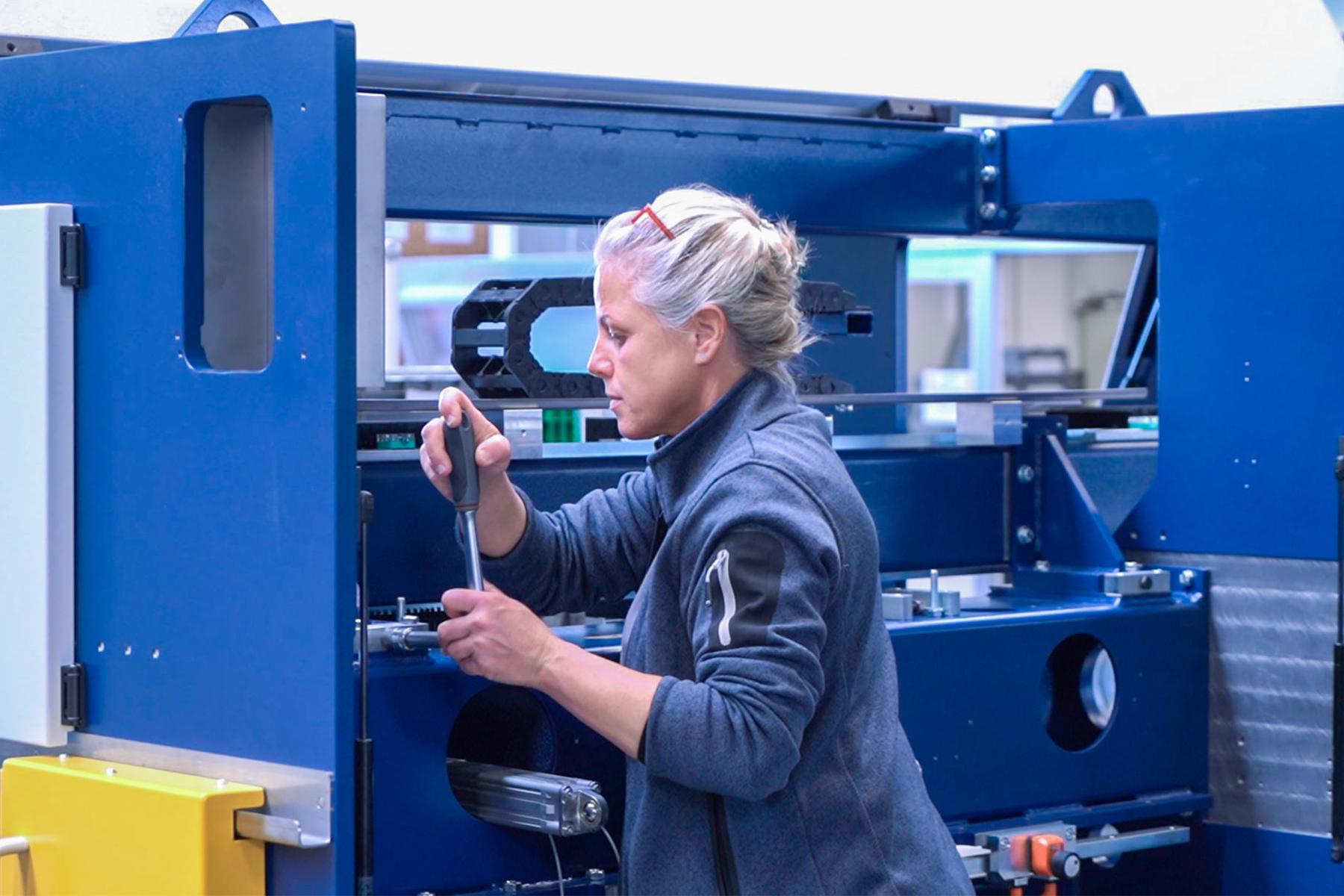

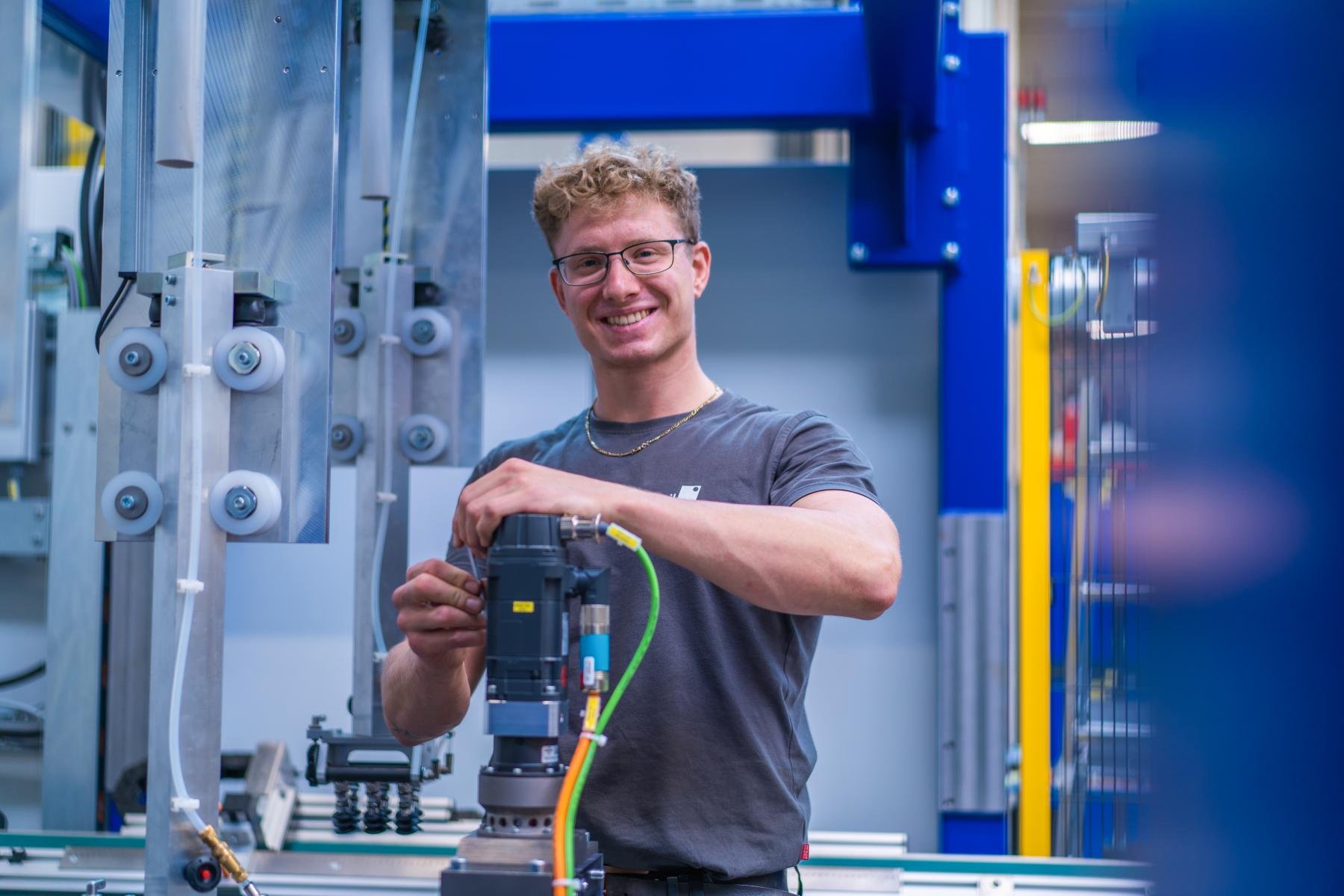

Production

Diversity in the assembly hall

Our tasks include the mechanical assembly of machines and complete plant wiring. Then the complete machines and production lines are commissioned ready for production and pre-accepted by the customer at our premises in Müllheim under production conditions. After customer approval, we dismantle the machines again and ship them to the customer all over the world, where we reassemble them and put them into operation again. After training of the operating staff and the final production release by the customer on site, the handover to our service department takes place.

-

Electrical design

Bringing machines to life

Our electrical designers use the "EPLAN" tool to plan the control cabinet and the electrics of our systems on the basis of a machine description. Customer specification as well as applicable standards are to be taken in account in the process. The programmers prepare the SPS programme, the drive technology and the visualisation offline. During commissioning, the process and the cycle time are optimised. For larger systems, the programmer is also at the customer's site to integrate the machine into a line or link it to a robot, for example. There is close cooperation with our mechanical design, project management as well as the commissioning engineers. There is also frequent consultation with suppliers and customers.

-

Material Management

Prudent storage

The warehouse management with goods receipt at Weil Technology ensures the receipt of our production goods, their correct allocation and distribution to the various assembly stations. Here it is necessary to coordinate with the various electrical and mechanical production departments within short deadlines so that there are no interruptions in the assembly process. This department is responsible for the storage of our parts at the site. When receiving goods, it is very important to correctly allocate quantities and different commissions. Unloading large components, visual inspection, quantity control, etc. are part of the daily routine.

-

Mechanical design

Individually planned machines

In the mechanical design department, all plant and machine concepts are created. We design complete systems, assemblies and individual parts of our machines for sheet metal processing with innovative laser, clamping and automation technologies. We also manage the data of our systems and create assembly plans. Internally, we work in an interdisciplinary manner, in particular with the electrical design department, project management and the fitters and commissioning engineers. We are also in constant exchange with customer and suppliers.

-

Purchase

Wide range in procurement

Purchasing at Weil Technology has a high priority because we do not manufacture any components and parts for our machines ourselves. This means that everything we need for the production and assembly of the machines and systems is purchased and procured. Therefore, it is of great importance that we establish and maintain stable supply chains and long-term partnerships in purchasing. The spectrum of purchasing covers a wide range of electrical and fluid engineering as well as steel construction and mechanically machined parts. This creates a very varied and also challenging working environment where it never gets boring.

-

Service

Where travel meets technology

In service, we support our customers worldwide with maintenance, servicing and repairs of their specific machines and production lines. Our solutions include routine operations such as preventive maintenance or operator training, but also individual support in the event of process problems. Furthermore, we offer complex retrofit conversions of existing equipment. Reliability is one of our principles in machine and plant construction as well as in service. We respond openly and flexibly to our customers' wishes - in Germany, Europe and all over the world. The locations where we work are often attractive destinations for after-work or weekend excursions.

Contact

You have questions about a career at Weil Technology?

Kim Alisa Becherer will be happy to answer your questions.