Mobility

With our machines and systems we support the requirements of the automotive industry

Innovative manufacturing solutions for the mobility industry

With our machines and systems, we support the requirements of the automotive sector in order to identify potential, optimize production and face the key challenges in ever-changing industry. For our customers, manufacturers of special vehicle components, the automotive sector is one of the most important sales markets. To meet the high demands of the automotive sector, which is undergoing major change, we work continuously with them to optimize manufacturing processes and products.

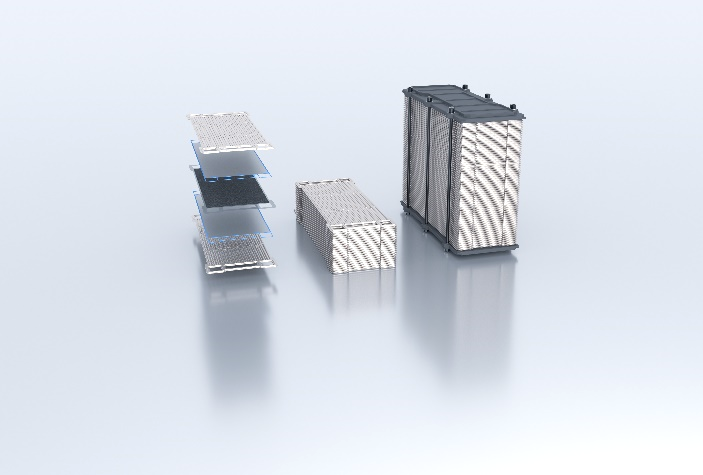

Selection of products manufactured on our machines and equipment in the field of e-mobility

Laser welding of stator packs

Laser welding and cutting of bipolar plates

Laser welding of high voltage heaters

Laser welding of stainless steel cell housings

Punching of radiator fins for power coolers

Cell contacting by laser welding

Contact Plate

Laser cutting of electrical sheets

Selection of products manufactured on our machines and equipment in the field of mobility

Exhaust gas component

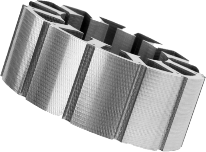

Radiator fins

Steering column

Exhaust inner tube

Exhaust valve

Compensator housing

Mixer truck

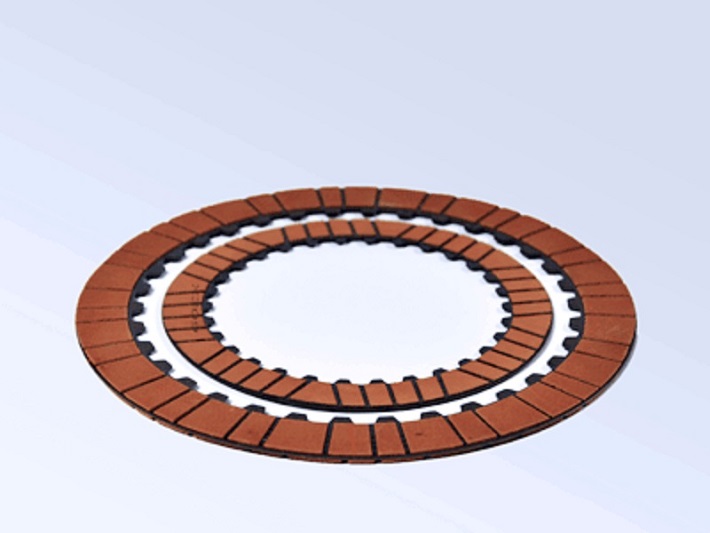

Clutch plate

Challenges of the industry

-

Low weight

Whether for vehicles with combustion engines or electric vehicles – weight reduction is one of the most important goals in the automotive sector. Material substitution of castings by sheet metal components can contribute significantly to achieving advantages in terms of weight. -

High profitability

Cost pressure in the automotive sector is enormous, while margins are low. In addition to innovative manufacturing methods (e.g. automated laser cutting, laser welding), improvements in processes and in the use of materials provide many advantages. -

Strong product quality

In the automotive sector, defects easily lead to significant effects on image and sales. Our fully automated systems, if required, ensure stable processes and thus consistent quality at a high level.

-

Low material costs

Inefficient use of materials not only increases the weight of components, but also your costs. With process and feasibility studies, we give you solutions for optimization and provide you with advantages over your competitors. -

Reliability

Just-in-sequence production at carmakers is based on flexible and reliable suppliers. We equip your production with these features and reduce downtimes.

-

Your general advantages

• Cost optimized manufacturing

• High productivity

• Reduced downtime

• Pre-validation

-

Why is Weil Technology the solution for you?

• Material substitution of castings by sheet metal components can contribute significantly to weight reduction.

• If fully automated systems are required, they ensure stable processes.

• With process and feasibility studies, we can advise on the optimum design of your components to suit your production. Depending on your requirements, we select the appropriate welding process and determine the ideal process parameters in initial sample parts.