Samples, prototypes and small series by order

From one up to 1.000 pieces

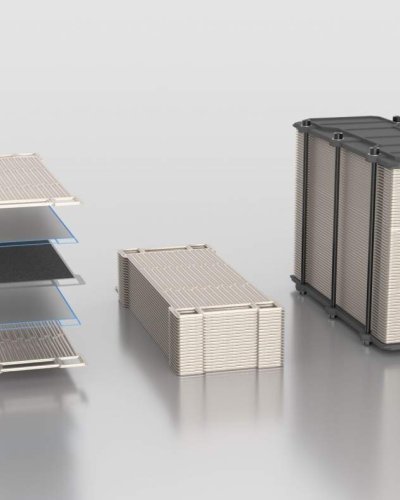

We have been developing and manufacturing production systems for flexible short pipe production for decades. We are now combining our expertise and the production capabilities of our machines and systems to create a new range of services:

Samples, prototypes and small series by order

We produce your metal tubes to measure, starting from one piece and up to an annual quantity of 1,000 pieces. This offer is ideal for the production of samples, prototypes or small series.

Our service for you

We advise you on the optimal process and production-suitable design of your component. Depending on your requirements, we select the appropriate welding process and determine the ideal process parameters in initial sample parts.

On the basis of a valid process and the ideal component geometry, we produce the first prototypes for you as a basis for checks and revisions and also offer pilot runs and sampling. We accompany you as a competent partner on the way to the production-ready component.

With our equipment we can produce parts in small series up to an annual quantity of 1000 pieces. You need a higher output quantity? After consultation, we can put you in touch with a suitable supplier with our systems.

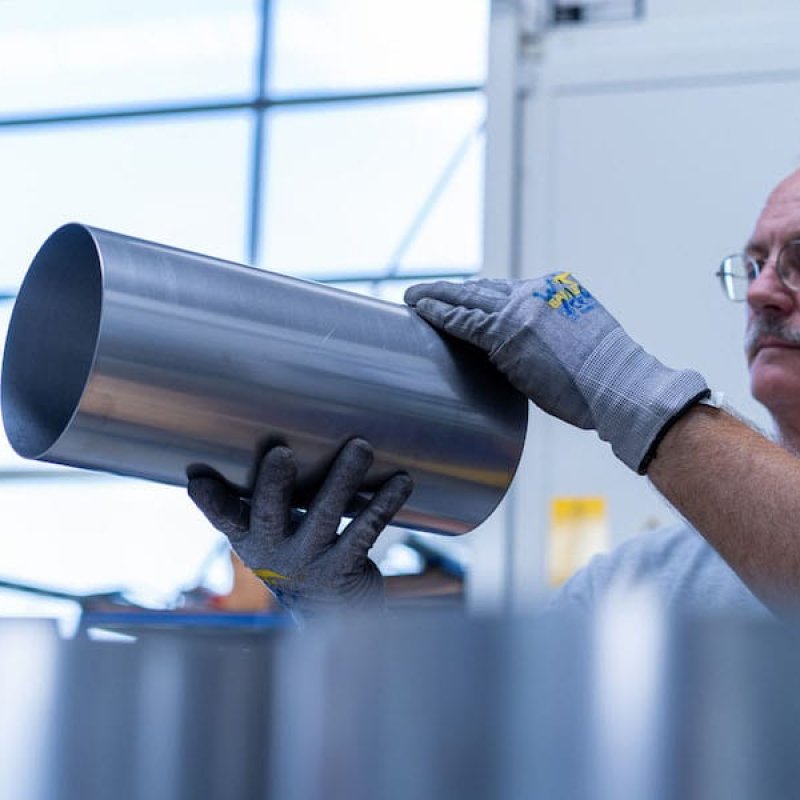

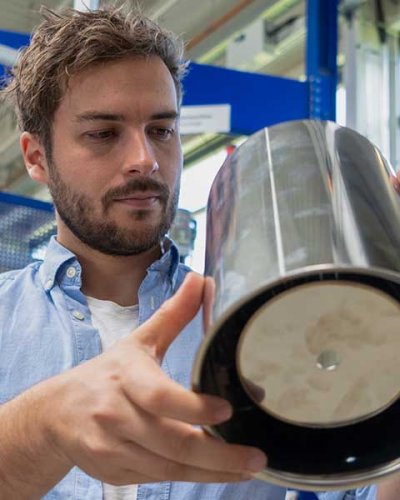

The tubes are produced from metal and printed circuit boards. They are formed into slotted tubes using a rounding technique appropriate for the material and then longitudinally welded. The roundness of the tubes is about 1% of the outer diameter. Other geometries are possible and can be requested.

This flexible manufacturing process enables us to produce tubes in all materials suitable for welding and in the following dimensions:

- Diameter: 80 - 450 mm

- Wall/material thickness: 0.3 - 3 mm

- Length: 20 - 1200 mm

We are happy to use the blanks or material from our stock that you provide.

Please note the table below. Dimensions outside the matrix must be checked for producibility.

We use laser welding as the welding method for most of the tubes. In the case of large wall thicknesses, cold wire is additionally used during the welding process to obtain a more stable weld seam. The offer is rounded off by the following additional services:

- Dimensional inspection

- Expansion via cone or step expander

- Macrosections to ensure the seam quality

Contact

Do you have any questions about small series production or would you like some non-binding advice? Then don’t hesitate to contact us

Andreas Graf, Head of TechCenter gladly answers your questions.

+49 7631 1809 536