Flexible Laser Solutions

Efficient laser cutting and welding of sheet metal assemblies:

flexible, modular, productive

You want to laser cut and/or weld sheet metal assemblies efficiently?

In small, medium or large quantities?

With high product diversity?

In a few operations flexibly, automatically and with high precision?

With integrated additional manufacturing technologies?

In highly productive cycle times?

We know: different batch sizes and fluctuating incoming orders currently characterize production.

Take advantage of the versatile variable system technology of our Flexible Laser Solutions for the production of sheet metal assemblies with individual concepts:

Quick-change systems of the component-specific clamping devices enable a short-cycle product changeover

A flexible basic machine enables the production of a wide variety of products simply by changing the clamping device

One-time clamping and coordinated machining optics ensure high repeatability that meets the highest quality standards

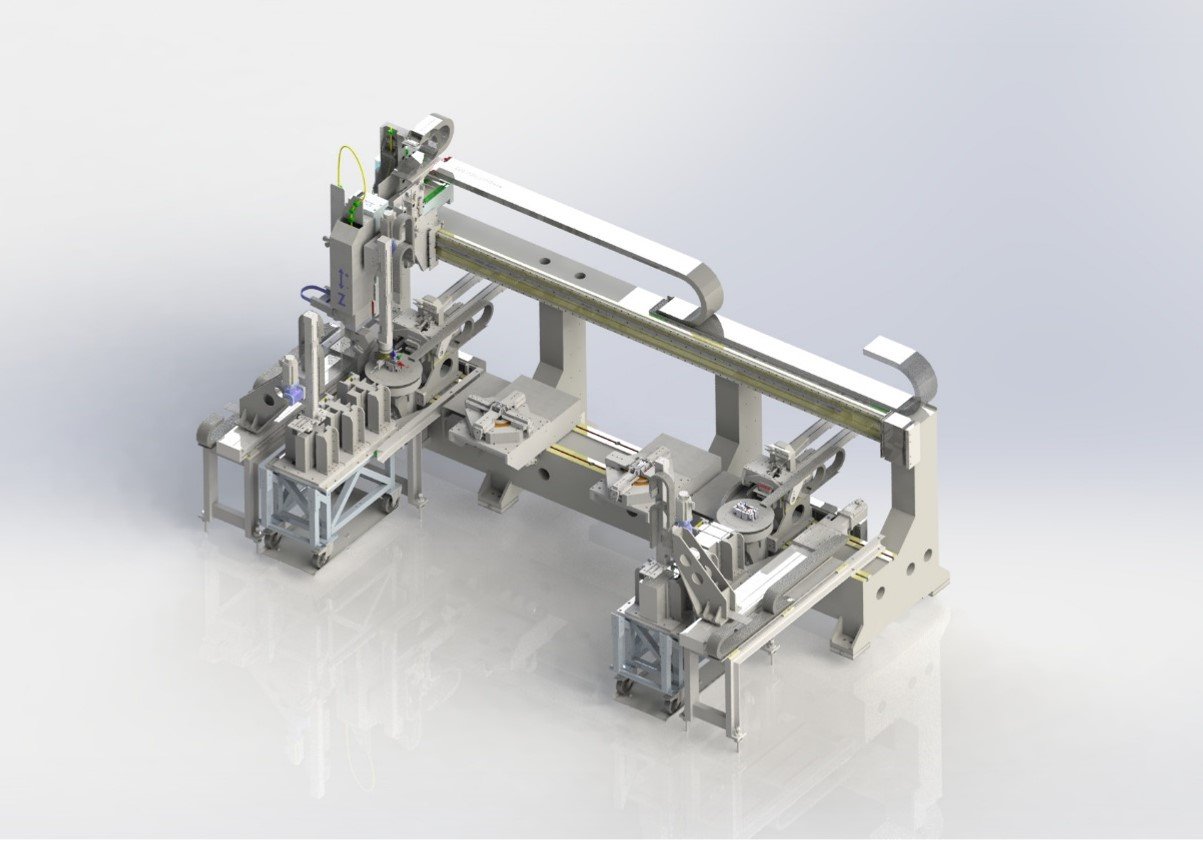

FLC – Flexible Laser Cell for maximum flexibility

Laser processing of 3D sheet metal assemblies shows high potential for economical production with high design freedom and flexibility. With our flexible laser cell, we can laser cut and laser weld in one machine - saving time, handling, labor and space while ensuring maximum precision.

The combination of up to three laser processing optics in the FLC allows 3D cutting and welding operations in one setup, with additional axes on the clamping device. Non-value-adding setup and transport times as well as buffer formation are eliminated by combining work sequences in one processing station. Via laser management, all processing optics are supplied by the same laser beam source. Thanks to the flexible configuration of processing optics and beam sources, the cutting and welding task can be optimally mapped. The result is maximum quality.

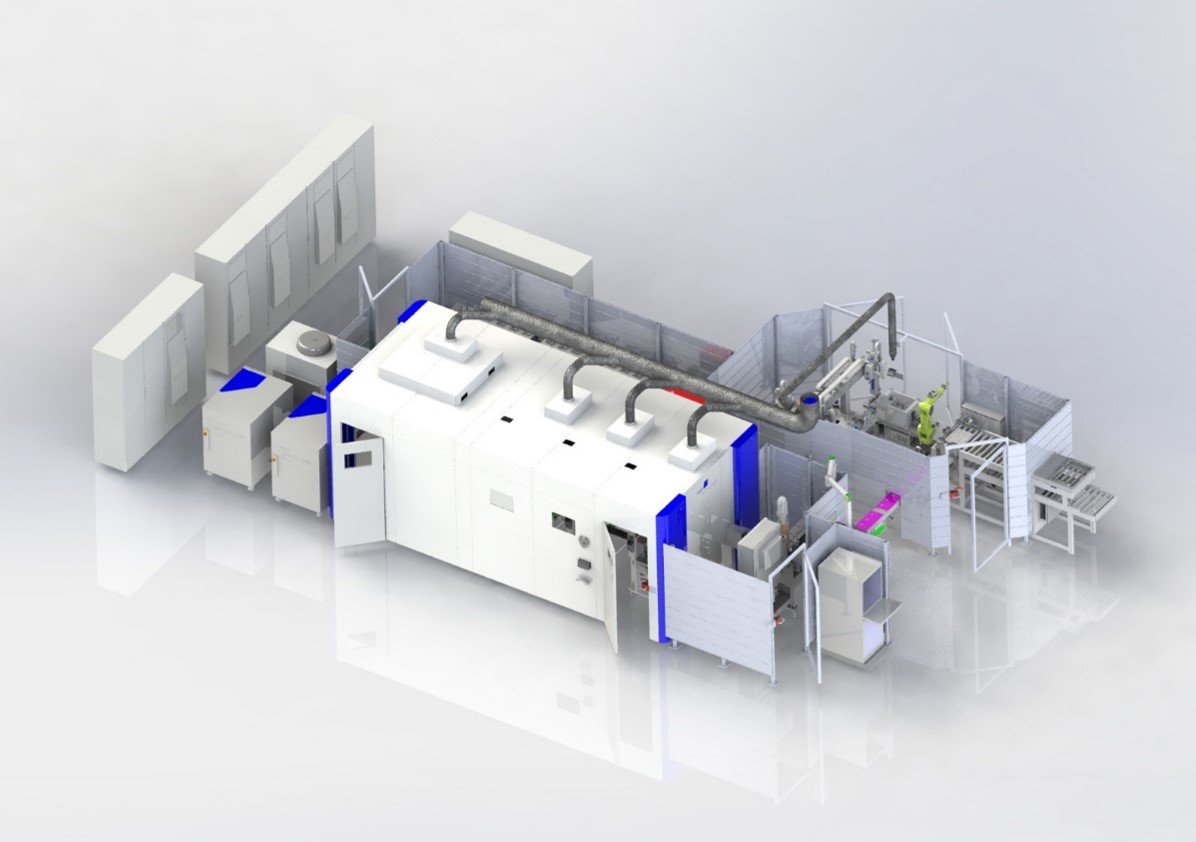

MLC – Modular Laser Cell for maximum modularity and automation capability

The MLC impresses in sheet metal processing with its modular system technology. It offers the combination of laser cutting or welding with additional manufacturing technologies such as bending, punching, embossing, laser marking, etc. and is optimized for multiple nest processing in one process cell and sectional processing of large components.

The modular design of the MLC allows high scalability. It can be used as a stand-alone system as well as for linking several lines in one system. Depending on the product requirements, project-specific production modules can be integrated into the system and coupled with each other.

LWM – Laser Welding Module for maximum productivity

In the LWM is a product-specific plant technology for maximum output. It is highly productive for the production of standardized components in large batches. The modular system enables simple, manageable processes and the combination of assembly, welding and testing tasks.

In the concatenation by the workpiece carrier system, leak testing stations, laser marking stations and palletizing systems can be integrated. As each module can be used and configured individually, the production of complex assemblies is possible. Robust clamping devices guarantee maximum accuracy. The division of the individual processes allows individual adaptation of detailed tasks.

You would like to learn more about the possibilities of efficient laser welding and cutting of sheet metal assemblies with our Flexible Laser Solutions?

Contact us!